|

Design B Series

For model MH-9B

/ 10B

Guided by

the motto, “Simple is best”, we worked

to create a structure that diminished

vibrations as much as possible, in order

to reduce the source of distorted sound.

The structure of the essential arm rest

/ arm lifter / anti skate mechanism has

been made of soft plastic (ABS) so that

unnecessary vibration can be reduced.

We have used hard stainless steel in the

arm tube, as it is the part most

dependent on sound quality. As a result,

the sound quality rises well and

finishes with a crisp sound.

If the fulcrum, which is essential for

sound quality, is a weak structure, it

will reverberate and directly impact the

sound quality. In this machine, the four

large bearings are firmly supported,

preventing resonance and shake, and

providing the ability to trace smoothly.

The points

where each part joins another are

designed to be in tight surface contact

to avoid using adhesive as much as

possible. In particular, the assembly of

the bearings requires meticulous

sensitivity.

We took a lot of trouble over the

curvature of the arm, to ensure that it

would not become a hard-to-control

structure manipulating a straight rod.

(Imagine how an extra twisting force is

applied by the hand when you manipulate

an L-shaped bar.) On top of that, we

placed “vibration absorbing structures”

in the most suitable place, thereby

effectively damping the resonance.

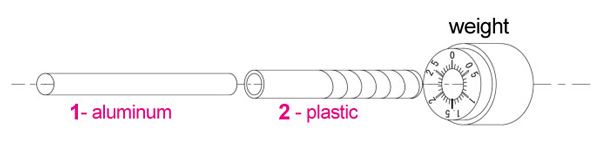

For the weight section, we have used two

different damper materials: 1-

aluminium, and 2- plastic (ABS),

constructed to absorb unnecessary

vibration over a wide area, regardless

of deterioration in the rise.

|